Case studies

The potential applications of quantitative forecasting are vast.

Below is a non-exhaustive list of scenarios where model predictions address challenges related to product development.

Lubricant effect on formulation flow

In recent years, external lubrication has gained interest as an alternative lubrication method. As the lubricant is directly applied on the tablet tooling and not incorporated in the formulation, a lubricant applied via external lubrication is assumed to have less impact on the tablet properties. However, this implicates that the positive effect of the lubricant when it is internally mixed on the formulation flow is not present anymore. This makes the selection of a free flowing formulation a bit more challenging.

Discover more

Evaluating ejection stress in direct compression

The ejection force - the force needed to remove the tablet from the die - can lead to defects like capping or lamination when too high. It is influenced by factors such as compaction pressure, compaction speed, and formulation composition.

Continue reading

Predicting occurrence of microcracks in tablets

Case study on leveraging tablettability predictions for early detection of mechanical instability.

Continue reading

Glidant addition to increase the maximum processable API content

The majority of new APIs have particle sizes below 80 µm, making them prone to agglomeration and poor flowability, possibly resulting in low maximum processable concentrations in formulations. Estimating which additional concentration margin is gained by adding glidant can be performed using formulation flow models.

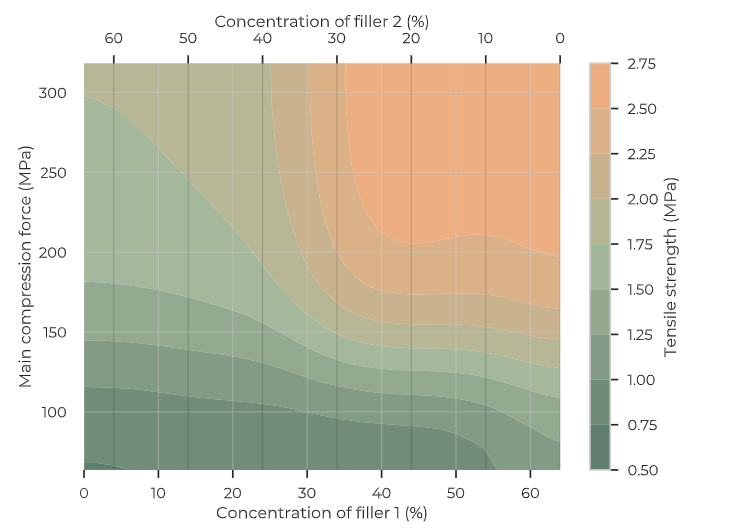

Evaluation of filler ratio at fixed API concentration

When zoned in on a certain API concentration, models and visuals created with them can provide swift decision support help for filler ratio evaluation.